The HPTAS is made up 3 fundamental components:

1) High stiffness, high capacity load frame

2) Pressure control for cell and back pressure

3) High pressure triaxial cell

Each of these components has a number of options depending on the stresses required for testing and the required sample size. The GDS 8 channel serial pad is used for data acquisition. This 16 bit device has 8 computer controlled gain ranges specifically designed to suit transducers used in a testing test i.e.

- +/-10mV, +/-20mV, +/-30mV (load cells)

- +/-100mV, +/-200mV (pressure transducers)

- +/- 1V, +/- 5V, +/- 10V (displacement transducers)

The system is controlled by the user’s PC running Windows® and GDSLAB software. GDSLAB enables multiple devices to be connected and so data acquisition as well as additional controllers may be added to the setup at any time as required. The operator chooses the type of test from a test menu (eg U-U, C-U, multi-stage, CRS, K0, stress path etc) and then enters the test parameters (of cell pressure, back pressure, testing rate and so on) and test termination conditions. The test then proceeds automatically with all test data being saved to a file. Tests can proceed overnight and during weekends and holidays. The computer directly controls the cell pressure, back pressure and testing rate. In addition to logging these parameters to the PC hard drive, the computer also logs axial displacement, axial load, pore pressure and volume change. Of course, additional transducers may be easily configured and logged during the test.

The GDSVIS load frame (Virtual Infinite Stiffness) is a unique GDS development. To the observer, and in terms of the test specimen, it allows the axial loading system to operate as though to have infinite stiffness.For the entire loading range, both the measurement and control of platen displacement is automatically corrected so that it corresponds to the deformation that occurs between the platen and the load button of the load cell. In this way, the platen displacement is corrected for strain in the load cell and side columns, bending flexure of the cross beams, and distortion within the motorised mechanical transmission.

The GDSVIS is computer calibrated to provide precise data on the load-deformation relationship of the entire load application and load measuring system. These measurements are made with the adjustable upper cross beam in the maximum and minimum positions. For each position, measurements are made with the platen at each end of its travel.

The calibration data is loaded into the read only memory (ROM) of the system which constantly monitors the axial load and uses the calibration to apply a correction to the platen displacement. Therefore, it appears to the observer (or controlling computer) that the measurement of platen displacement (resolved to 0.1 micrometre) is derived from a machine with infinite stiffness. In this way the system has the characteristic of Virtual Infinite Stiffness.There are a number of clear advantages with the GDSVIS load frame over a hydraulically powered machine. An extremely accurate ballscrew and gearbox arrangement is used. This electromechanical approach allows very fine and accurate monotonic control to be performed.

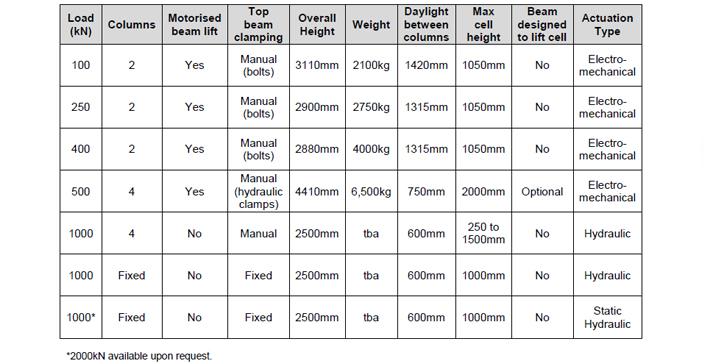

Load frame options

The largest electro-mechnaical load frame in the GDSVIS range is the 500kN version. This four column frame can hold a cell size of with a 700mm outer cell diameter. The optional additional height of the 500kN load frame is to allow the cell top to be raised and lowered by the upper cross beam as it raises and lowers. Hydraulic column locks replace the standard torque wrench’s tightened locks, allowing the user quicker clamping force when adjusting the height of the frame or lifting the cell top. For more information on the VIS load frames, see the dedicated datasheet for the frames (GDSVIS).

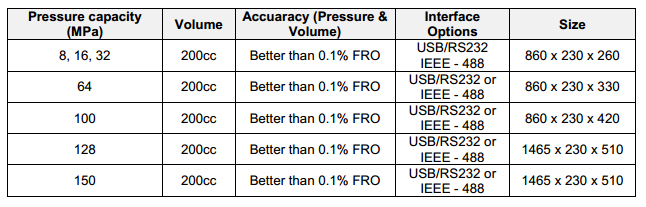

Pressure / Volume Controller options

The High Pressure pressure / volume controllers may be used for the cell and back pressure. The controllers have pressure ranges of up to 150MPa, serial or IEEE PC connectivity and 200cc volumetric capacity.

For more information on GDS pressure/volume controllers, see the dedicated datasheet for Advanced Pressure controllers (ADVDPC).

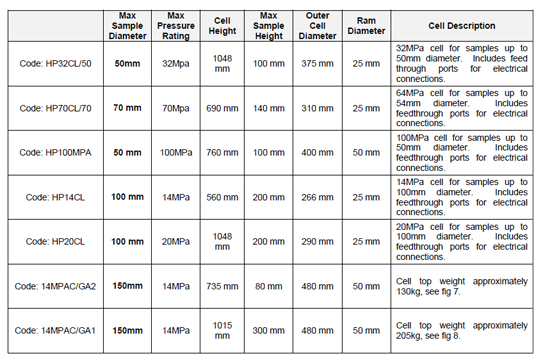

Cell Options

GDS produce an extensive range of triaxial cells in order to satisfy the complex range of High Pressure tests required by today’s modern geotechnical laboratories. Cells suitable for use in a load frame are known as passive cells (known as passive due to the fact that they are used with an external actuator such as a load frame to apply axial loads). There are 2 types of passive triaxial cells, those without a balanced ram and those with. In addition, there are a number of features such as, access ports and access rings for internal transducers.

High pressure cells without a balanced ram

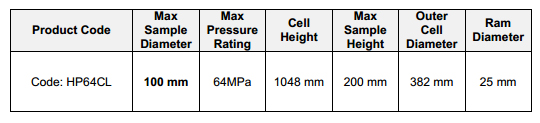

High pressure cells with a balanced ram

What is a Balanced Ram?

The balanced ram is a system that compensates for the up thrust on the ram exerted by the cell pressure. Our system utilises a secondary chamber around the ram that balances the pressure in the cell against a second piston seal such that the pressure load is not exerted onto the loadframe. This system usually means that a smaller range loadframe can be used to achieve the same deviator loadings on the sample. For example if a cell has a 50mm diameter ram and a cell pressure of 32MPa the up thrust would be approximately 63kN on the frame. This would have to be deducted from the maximum achievable deviator loading that a given frame can apply. With a balanced ram, the full load frame capacity may be used to apply axial force on the sample as there is zero ram upthrust. In addition, a balanced ram within a high pressure passive cell eliminates disturbance to constant cell pressure during axial loading.

Upgrade Options for HPTAS

Upgrade to Local Strain Measurement

Any GDSTAS system may be upgraded to perform Local Strain measurement using either Hall Effect or LVDT transducers. Both device types enable axial and radial deformation to be measured directly on the test specimen via lightweight aluminum holders. Hall Effect transducers may be used in water up to 1700kPa. LVDT transducers come in 2 versions:

- Low pressure (up to 3500 kPa) version for use in water

- High pressure (up to 200 MPa) version for use in nonconducting oil

Upgrade to Unsaturated Testing

For the HPTAS the only products you will require are unsaturated pedestal with high air entry porous stone. When testing unsaturated soils it is necessary to separate the pore-air and the pore-water so that differential pressures (known as matric suctions) can be maintained. This separation is achieved by the use of high-air-entry porous discs (HAEPD).

Upgrade to Bender Element Testing

Any GDSTAS system may be upgraded to perform P and S wave bender element testing with the addition of the following items:

- Bender element pedestal with bender element insert

- Bender element top-cap with bender element insert

- High-speed data acquisition card

- Signal conditioning unit which includes amplification of source and received signals (P and S-wave) with user controlled gain levels (via software).